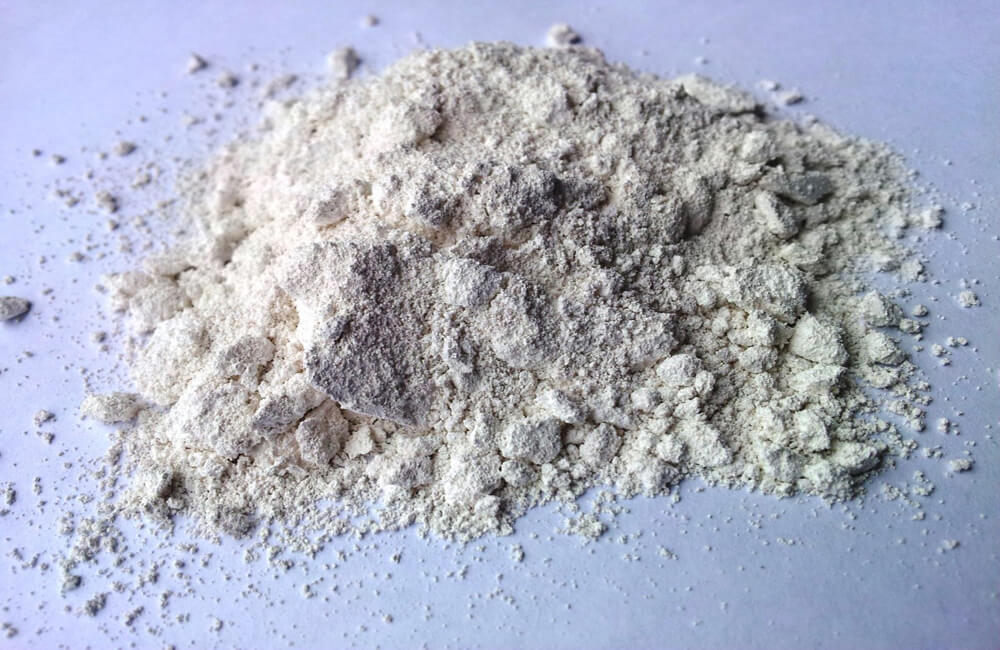

Structural changes in the market of chemical products associated with the withdrawal of foreign companies from the Russian market and the reduction of supplies of European raw materials began in 2022. However, successful practices of import substitution in Russia have already appeared. At the beginning of March at the International exhibition Interlakokraska-2023 an ultra-white pigment filler WPS 02, developed by the group of companies "Functional Materials" (FM Group) was presented for the first time. The additive is used in production of paintwork products and thick-layer decorative materials. The pigment can partially replace expensive titanium dioxide, which is used in the manufacture of paints and other types of coatings. Introduction of 10-20% of pigment instead of titanium dioxide reduces the cost without worsening the characteristics of the finished paintwork materials. The product has no Russian analogues.

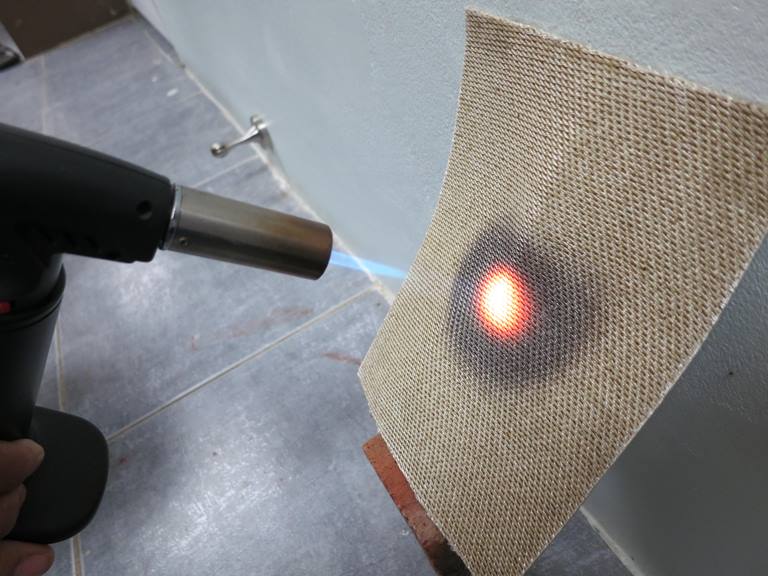

One more perspective Russian development is TIAL FM pigment which allows to increase corrosion resistance of special purpose paintwork materials. The pigment is more effective and on the average 1,5 times cheaper than the zinc phosphate traditionally used in the formulations. Until recently such products were presented in "niche" catalogs of German and Austrian manufacturers. From 2020 the chemical complex enterprises have the opportunity to buy the Russian-made corrosion-resistant pigment. Since its introduction to the market, the demand for TIAL FM has been growing every year; in 2022 its sales increased by 300% compared to the previous year.

The demand for aluminum hydroxide is predicted to increase in the coming years. According to the import substitution plan approved by the Ministry of Industry and Trade, by 2024 the share of this product of domestic production should grow from 30% to 50%. Last year the output volume of fine-graded aluminum hydroxide at the FM production facilities amounted to 1330 tons.

"The process of replacing imported raw materials with a competitive Russian product requires the development of cooperative ties between chemical complex enterprises and research and production sites. Expertise of our companies allows us to transform innovative developments into products demanded by the market and ensure its production in the required volume, "- said Polina Zhuravleva, director of the North-West Nanocenter.

Chemical industry is one of the most important industries of the Russian economy, producing goods for engineering industry, pharmaceutics, construction and finishing materials, agriculture. One working place at the enterprises of the chemical industry creates about 7 vacancies in the related industries. The domestic market of chemical products is highly dependent on imported raw materials. According to Association of Paint and Varnish Manufacturers "Tsentrlak", the share of imported components in production of paint and varnish materials is up to 70%. Reducing the industry's dependence on foreign suppliers is one of the priorities of the government's economic policy. The list of import substitution projects up to 2030 published by the Russian government at the end of the last year contains the largest share of the chemical industry production - 33%. The products presented at the exhibition demonstrated the ability of Russian manufacturers to quickly adapt to the external environment and create competitive raw materials and components for the chemical industry.